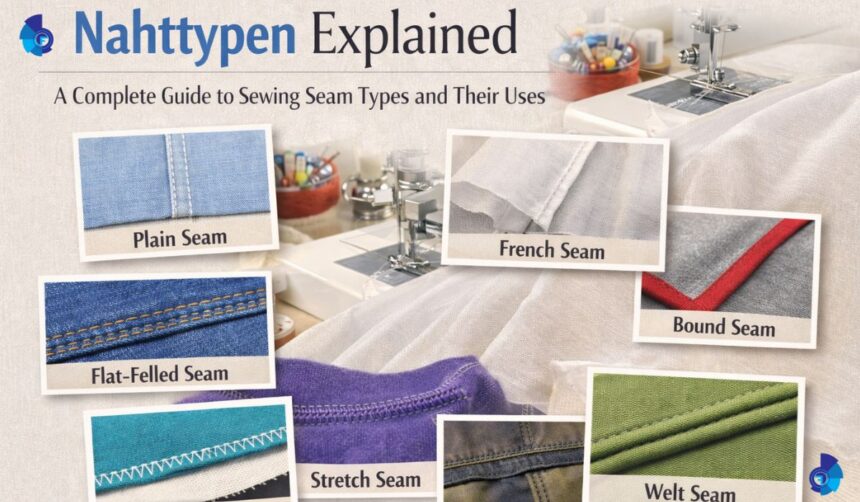

When you look at a finished garment, your eyes may notice the fabric, color, or fit first. What often goes unseen is the structure holding everything together. That structure comes from carefully chosen seams. Understanding different Nahttypen is essential for anyone who sews, designs clothing, studies fashion, or simply wants to understand how garments are built. Seam types affect comfort, strength, stretch, durability, and appearance. They can make the difference between a garment that lasts for years and one that falls apart after a few washes.

This guide explains seam construction in clear and simple language. Whether you are a beginner using a home sewing machine or an experienced maker refining your skills, you will learn how different seam styles work, when to use them, and why they matter in both fashion and functional sewing.

Why Seam Types Matter in Garment Construction

Seams are more than lines of stitching. They shape fabric into three-dimensional form. They allow movement. They protect raw edges from fraying. They support stress points such as shoulders, waistlines, and armholes. The choice of seam affects how fabric behaves over time.

For example, a delicate silk blouse requires a different approach than a pair of denim jeans. Lightweight fabrics need clean finishes that do not show through. Heavy fabrics demand strong construction that can handle tension. Activewear needs stretch and flexibility. By choosing the right seam construction, you improve both the look and the life of a garment.

The Plain Seam: The Foundation of Sewing

The plain seam is the most basic and widely used seam in sewing. It is created by placing two pieces of fabric right sides together and stitching along the edge. After sewing, the seam allowances are usually pressed open or to one side.

This simple method works well for woven fabrics and everyday garments. It is easy to sew and quick to finish. However, the raw edges may fray if they are not finished properly. That is why plain seams are often combined with finishing techniques such as zigzag stitching, pinking, or serging. While basic, this seam forms the backbone of most clothing construction.

French Seam: Clean and Elegant Finish

A French seam is often used for lightweight or sheer fabrics like chiffon or silk. It encloses the raw edges inside the seam, creating a neat and polished finish on the inside of the garment.

This method involves sewing the fabric wrong sides together first, trimming the seam allowance, then turning the fabric right sides together and stitching again. The result is a smooth interior without visible raw edges. French seams are ideal for delicate blouses, lingerie, and children’s clothing. They are not suited for thick fabrics because the multiple layers can create bulk.

Flat-Felled Seam: Strength and Durability

The flat-felled seam is known for its strength. It is commonly seen in jeans and workwear because it can handle heavy stress. In this seam, one seam allowance is trimmed, and the other is folded over it and stitched down flat.

This creates a strong, enclosed seam with two rows of visible stitching on the outside. It prevents fraying and adds durability. Although it takes more time to sew than a plain seam, it offers long-lasting performance. This is why it is popular in garments that experience frequent movement and washing.

Bound Seam: A Decorative and Protective Option

A bound seam encloses raw edges with a strip of fabric or bias tape. This technique protects the seam allowance while adding a decorative touch. It is often used in unlined jackets or high-end garments where the inside is visible.

Bound seams provide both strength and beauty. They work well on medium-weight fabrics. However, they may add slight thickness, so they are not ideal for very lightweight materials. When done carefully, this finish can elevate the overall quality of a garment.

Lapped Seam: A Practical Alternative

A lapped seam is created by overlapping one piece of fabric over another and stitching it in place. This seam does not require the pieces to be placed right sides together first. It is commonly used in leather, suede, and non-fraying fabrics.

Because the raw edge remains exposed underneath the overlap, it works best on materials that do not unravel. Lapped seams are also used for decorative effects, as the topstitching can become a design feature. This method provides moderate strength and a distinctive appearance.

Zigzag and Overlocked Seams: Preventing Fray

To prevent fraying, many home sewers use zigzag stitching along raw edges. A sewing machine can create a zigzag pattern that secures the threads and keeps fabric from unraveling. This is a practical solution for woven fabrics.

An overlocked seam, created with a serger, trims and finishes the edge in one step. It wraps thread around the raw edge, creating a clean and stretchy finish. Overlocked seams are common in ready-to-wear clothing. They are fast and efficient, making them ideal for mass production and knit garments.

Stretch Seams for Knit Fabrics

Knit fabrics require seams that can stretch without breaking. A straight stitch may pop when the fabric stretches. For this reason, stretch stitches or narrow zigzag stitches are often used.

A serger is especially helpful for knit garments because it allows the seam to move with the fabric. Athletic wear, t-shirts, and leggings depend on flexible seam construction. Choosing the right technique ensures comfort and durability, especially in clothing designed for movement.

Welt Seam: Adding Structure and Style

A welt seam is formed by placing a strip of fabric, known as a welt, between two pieces of fabric before stitching. The welt is visible on the outside and adds both strength and design detail.

This seam is often used in tailored garments, upholstery, and decorative sewing. It can highlight lines in a jacket or coat. While it requires careful measurement and precision, it offers a professional finish that enhances structure and appearance.

Taped and Reinforced Seams

In garments that face heavy wear, seams may be reinforced with tape or additional stitching. Shoulder seams in t-shirts are often stabilized with seam tape to prevent stretching. Outdoor clothing may include sealed seams to protect against water.

Reinforcement improves durability and shape retention. In sportswear and outerwear, this detail helps garments perform better in challenging conditions. Though not always visible, reinforced seams play a major role in garment quality.

Choosing the Right Seam for Your Fabric

Selecting the right seam depends on fabric type, garment purpose, and desired finish. Lightweight fabrics benefit from enclosed finishes. Heavy fabrics require strong construction. Stretch fabrics need flexibility. Decorative garments may call for detailed or visible stitching.

Before sewing, it helps to test seam options on scrap fabric. Pressing is also important. Proper pressing shapes the seam and improves its appearance. By matching seam construction to fabric characteristics, you achieve better results and longer-lasting garments.

Common Mistakes and How to Avoid Them

One common mistake is using the wrong seam for the fabric. For example, applying a bulky seam to thin fabric can create stiffness. Another issue is skipping seam finishing, which may lead to fraying over time.

Incorrect seam allowance measurement can also cause fitting problems. Always follow pattern instructions and measure carefully. Press seams as you sew, not just at the end. These simple habits improve both appearance and durability.

Understanding different Nahttypen reduces these errors and builds confidence in your sewing skills. Experience and practice will help you recognize which method works best in each situation.

Seam Types in Modern Fashion and Industry

In today’s clothing industry, seam construction balances speed, cost, and quality. Mass production often relies on overlocked seams because they are efficient. High-end fashion may use French or bound seams for a polished interior.

Sustainable fashion also considers seam durability. Strong seams extend the life of garments, reducing waste. Technical clothing uses specialized seams for waterproofing or flexibility. Seam choice reflects both design goals and performance needs.

As sewing technology evolves, new machines and techniques continue to improve seam quality. Yet the core principles remain the same. Understanding fabric behavior and construction basics is key.

Final Thoughts

Seams may seem like a small detail, but they shape the entire garment. From the simple plain seam to advanced reinforced finishes, each method serves a purpose. Learning about different seam constructions helps you make smarter choices, whether you are sewing at home or studying garment design.

Nahttypen are not just technical terms. They represent the structure, strength, and character of clothing. By understanding how each seam works and when to use it, you gain control over quality, comfort, and style. With practice and careful attention, your sewing projects will look more professional and last much longer.

Frequently Asked Questions (FAQs)

1. What are Nahttypen in simple terms?

Nahttypen are different types of seams used in sewing to join pieces of fabric together. Each seam type has a specific purpose. Some are designed for strength, others for flexibility, and some for decorative or clean finishing. Choosing the right seam depends on fabric and garment style.

2. Which seam type is best for beginners?

The plain seam is usually best for beginners. It is simple to sew and works well for many basic projects. Once comfortable with this method, beginners can explore other seam finishes like zigzag or French seams for added durability or neatness.

3. Why are French seams used in delicate fabrics?

French seams hide raw edges inside the seam, creating a clean and polished finish. Delicate fabrics like silk and chiffon can fray easily, so enclosing the edges protects the fabric and improves appearance. It also makes the inside of the garment look neat.

4. What seam is strongest for heavy-duty clothing?

Flat-felled seams are among the strongest options. They are commonly used in jeans and workwear because they can handle tension and frequent washing. The double stitching and enclosed edges add durability.

5. Are overlocked seams better than plain seams?

Overlocked seams are not necessarily better, but they are efficient and prevent fraying. They are commonly used in ready-made clothing and knit fabrics. Plain seams can be just as effective when properly finished.

6. How do I choose the right seam for stretch fabric?

Stretch fabrics need seams that move with the material. A stretch stitch, narrow zigzag, or serger stitch works well. These allow the seam to stretch without breaking, which is important for comfort and durability.

7. Can seam choice affect the lifespan of a garment?

Yes, seam choice directly affects durability. A weak seam may tear or fray over time. A strong and appropriate seam improves structure and extends garment life. Matching seam type to fabric and use is essential for long-lasting clothing.

For More: fogmagazine.co.uk